How to open Oxygen Plant in India?

Oxygen Plant:

Oxygen plays a vital role in the respiration of human beings. Without oxygen, no human life is possible on the planet. Human beings and many other creatures on the earth requires oxygen to stay alive. Oxygen is naturally produced by plants during photosynthesis wherein plants take carbon dioxide and release oxygen into the atmosphere.

Oxygen is also used in hospitals to provide life support to patients and treat various diseases. Apart from this, oxygen is also used largely in the industries for the production of steel, plastics, textile, etc. Oxygen is a crucial component in the life support systems in submarines, aircrafts, space crafts, etc. However, these industrial needs of oxygen cannot be met by oxygen naturally produced by plants. It requires oxygen to be produced artificially on large scale to meet industrial needs.

An Opportunity in the Crisis

With the shortage of oxygen in the hospitals due to the second wave of covid-19 in India, the government has temporarily stopped the supply of oxygen for industries. This has led to a huge surge in the demand for oxygen in the country. With both hospitals and industries facing a shortage of oxygen, the industrial production of oxygen has come to a central stage across the country. The government is advising oxygen manufacturers to scale up the production in order to meet the growing demand and ensure sufficient reserves. This crisis is also a great opportunity for new entrepreneurs to start the oxygen manufacturing plant, considering the current situation in the country.

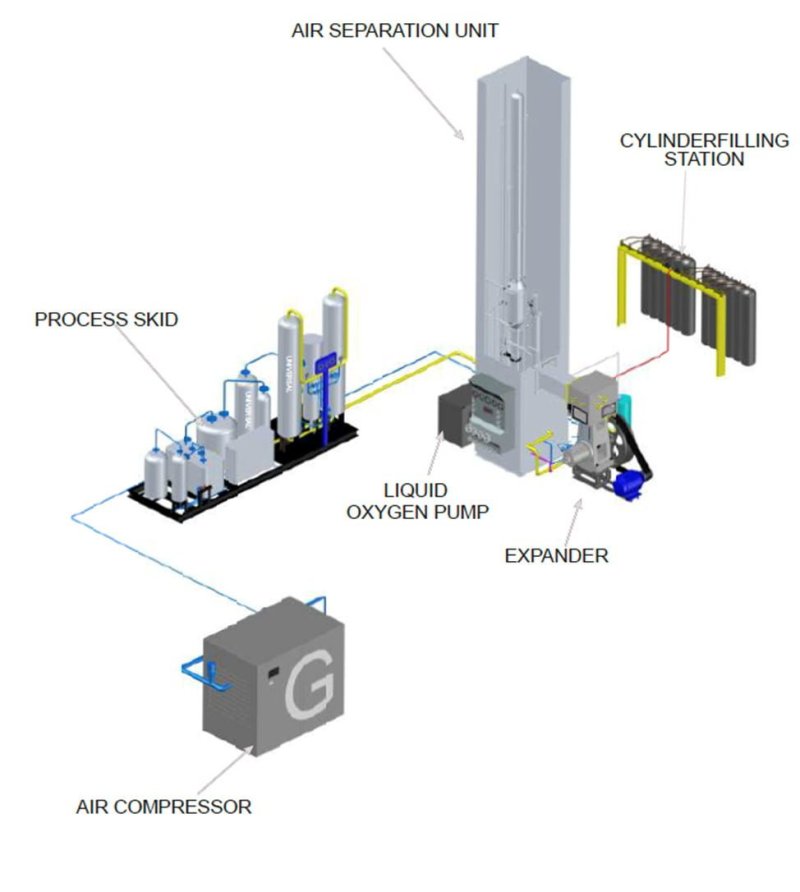

In this context, let us have look at how to start an industrial/medical oxygen plant. Oxygen is generally produced in various ways in industries. However, two methods are widely used to produce oxygen with 99.7% purity which is suitable for all kinds of industrial requirements.

Read More: How to open Hindustan Biodiesel Pump?

Types Of Oxygen Plant:

There are three types of Oxygen Plant:

- PSA (Pressure Swing Adsorption) Oxygen Plant.

- VPSA (Vaccum Pressure Swing Adsorption) Oxygen Plant.

- Medical Oxygen Plant.

1. PSA (Pressure Swing Adsorption) Oxygen Plant:

In this process, the air is taken from an air compressor and oxygen is separated from other gases, including nitrogen with the help of zeolite molecular sieves. The process involves two towers filled with zeolite molecular sieves which adsorbs nitrogen and subsequently discharge waste. The oxygen generated is 95% pure. When nitrogen saturates from one tower, this process changes over to the other tower, thus helping in the process of continuous oxygen generation.

Salient features:

- Full Automation.

- Lower space requirement.

- Fast start-up

- High Reliability.

Applications:

- Paper & Pulp Industries for leaching and delignification

- Glass Industries for furnace enrichment.

- Metallurgical industries for oxygen enrichment of furnaces.

- Chemical Industries for oxidation reactions and for incinerators.

- Effluent water and waste water treatment.

- Color and B&W Picture Tube/Glass shell industry.

- Brazing Application.

- Lamp/Compact Florescent Lamp Industry.

- For fishing Farming.

- Ozone Generation.

- LPG Enrichment.

Plant Equipments for PSA:

- Air Compression

- Filtration

- Drying

- Air Buffer Tank

- Trace Oil Particle Filter

- Air Buffer for pneumatic valve

- A) First Absorbing Tower A B) First Absorbing Tower B

- Flue Gas Vent Silencer

- Oxygen Surge/Buffer tank

- Booster Compressor

- A) Second Absorbing Tower A B) Second Absorbing Tower B

- Flue Gas Vent Silencer

- High Purity Oxygen Surge/Buffer Tank

- High Purity Oxygen Storage Tank

2. VPSA(Vacuum Pressure Swing Adsorption) Oxygen Plant:

The VPSA oxygen gas plant is available with air fan and Vacuum generator and have quick and convenient start and stop. This Oxygen plant has low automation and is user friendly. The plant provides pure oxygen by using Zeolite molecular sieves. Due to large capacity it uses vacuum assisted regeneration. Very suitable for flow rate above 200 NM3/hr.

How VPSA Principle works ?

This process consists of 2 beds filled with molecular sieves. These cycle alternately in production and in Regeneration of Molecular sieves is done by assistance of a vacuum pump. The waste gas is 85% Nitrogen and 15% Oxygen which is vented to atmosphere. Product oxygen gas purity is 90 to 85%.

Plant Equipment:

- Air Fan & Vacuum Pump

- Temperature regulating system

- Adsorption system

- Oxygen Buffer tank

- Control System Technical Index Oxygen.

Applications:

- Paper & Pulp Industries for leaching and delignification.

- Glass Industries for furnace enrichment.

- Metallurgical industries for oxygen enrichment of furnaces.

- Chemical Industries for oxidation reactions and for incinerators.

- Effluent water and waste water treatment.

3. Medical Oxygen Plant

Medical Oxygen plants serves as reliable source for the generation of continuous medical-grade oxygen for all your medical needs.

Plant Equipment:

- Air Compressor.

- Air cooling & Dryer Unit

- PSA Oxygen Generator

- Oxygen Tank

- PLC Control Panel

Application:

- On site supplying oxygen by piping net for human breath as the hospital oxygen center.

- Filing into cylinders and being transported to end-users.

- Restore tissue oxygen tension by improving oxygen availability in a wide range of conditions such as COPD, cyanosis, shock, severe hemorrhage, carbon monoxide poisoning, major trauma, cardiac/respiratory arrest

- Provide a basis for virtually all modern anesthetic techniques

ADVANTAGES

- No Raw Material

There is no Raw Material Required to produce Industrial/Medical grade Oxygen, as plant uses air from atmosphere to separate oxygen from Processed air.

- No Raw Material

Raw Material

The raw material for the Oxygen and Nitrogen (gas and liquid) is atmospheric air. Besides this, the plant will require consumables like lubricants, greases, catalysts and chemicals, which are available indigenously.

Water Requirement:

About 10,000 liters/day of water will be required for operation of the plant, which is proposed to be met from own bore-well. The ground water is too treated in a water treatment plant and is to be re-circulated through a Cooling Tower.

Manpower Requirement:

It is estimated that number of persons to be employed in this project is 50 considering 3 shift operations. The break-up of manpower will be as follows:

- Managerial :- 2

- Clerical :- 1

- Skilled :- 4

- Un-Skilled :- 6

Cost of the Project:

| Description | Rs in lakh |

| Land & Site development | 10 Lacs |

| Civil Cost | 6 lacs |

| Equipment & Electrification | 29 Lac |

| Other Fixed Assets | 5 lac |

| Total | 50 Lakh |

Means of Finance

The project is proposed to be funded from term loans from banks, financial institutions and Promoters’ Contribution in the ratio of 1.83:1. The proposed means of the finance for the project will be as under

| Description | Amount |

| Term Loan | 40 lakh |

| Working capital | 10 lakh |

| Total | 50 Lac |

Selling prices

The selling prices have been considered on the conservative side and less compared to the prevalent market rates at which the Company is currently selling its products from its existing unit.

Consumables

Consumables like lubricants, greases, catalysts and chemicals will be required, which is taken at 3.00 paise per Cubic Meter of goods manufactured.

Salary and wages

Provision for labor and supervision is based on the operational and maintenance manpower requirement of the unit. In addition to salary and wages as applicable to various grades, a provision has also been made towards fringe benefits. This has been taken as follows

| Description | No. of person | Salary per month |

| Manager | 1 | 18000 |

| Assistant manager | 1 | 13500 |

| Lab chemist | 1 | 8000 |

| Sales & Admin officer | 2 | 10000*2=20000 |

| Accountant | 1 | 6500 |

| Security | 1 | 9000 |

| Operator | 4 | 6000*4=24000 |

Other direct costs:

Other direct costs have been considered at 15.00 paise per Cubic Meter of goods manufactured.

Depreciation: Depreciation has been considered at straight line method as per the Companies Act.

Selling, distribution and general expenses: These have been assumed 12.50% of net revenue.

Interest: Interest has been considered at 11% p.a.

Documents Requirements for Oxygen Plant setup & Bank Loan:

- Applicant Adhar card & Passport

- Copy of Address proof

- Existing Land for Plant Setup

- Business Registration

- GST Registration Certificate

- Financial Documents for Loan (If loan required)

- ITR last 3 years

- Last 3 months Bank statements.

- Land area (20 kattha)

License Required:

- PESO (Petroleum & Explosives Department) License

- State Pollution control Board.

- OHSAS license

- Factory License

- ISO 9001:2015

- Fire & Safety department license

- Labor license.

- Trade License from local authority

- Power Load from power distribution company

- Village NOC (If required)

- Udhyam Registration

Investment for the Oxygen Plant:

Investment ranges from 50 lakhs – 50 crore (Depends on plant capacity).

For the Mini Oxygen plant

Investment required for Oxygen Plant Capacity 50-75 cylinder per day will be 26 Lac.

Cost Per cylinder oxygen (7cum)= Rs 70

Ex -factory price= 400-500

Profit will be very high in the Oxygen Plant.

Return on investment is very good.

Break Even reach within 1 year

For Installation & Commissioning of machinery and setup full plant contact

- Sam gas projects pvt limited :- 08048404443

- Universal Boschi, Rajasthan :- 08048762903

- Hitech Engineering Solutions, Punjab:- 91-1765-500999

- Airgases Projects (P) Ltd, Kolkata:- +91 9831098652

- M/s ABB India Limited:- 1800 420 0707

- VRV Asia Pacific Pvt. Ltd.:- +91 8623 304700

- Super Cryogenics Sys P Ltd:- 08048558528

- Cryolor Asia Pacific, Tamil Naidu

If you want to get help from our team then fill the contact us form, our team will contact you soon and help to setup oxygen plant.

Looking for oxygen plant for Medical application

Sir plz contact me I want to open a oxygen plant

Very helpful…thanks you for wonderfully work

Requirement For A PSA plant In Lucknow for Industrial as well as Oxygen